The In Rust We Trust Project: technological and cultural aspects of terrestrial experiments on a Martian clay simulant

Keywords: 3D Printing, Clay Printing, Mars, Ceramic, Experiment, Martian Clay Simulant, Archeology, Space.

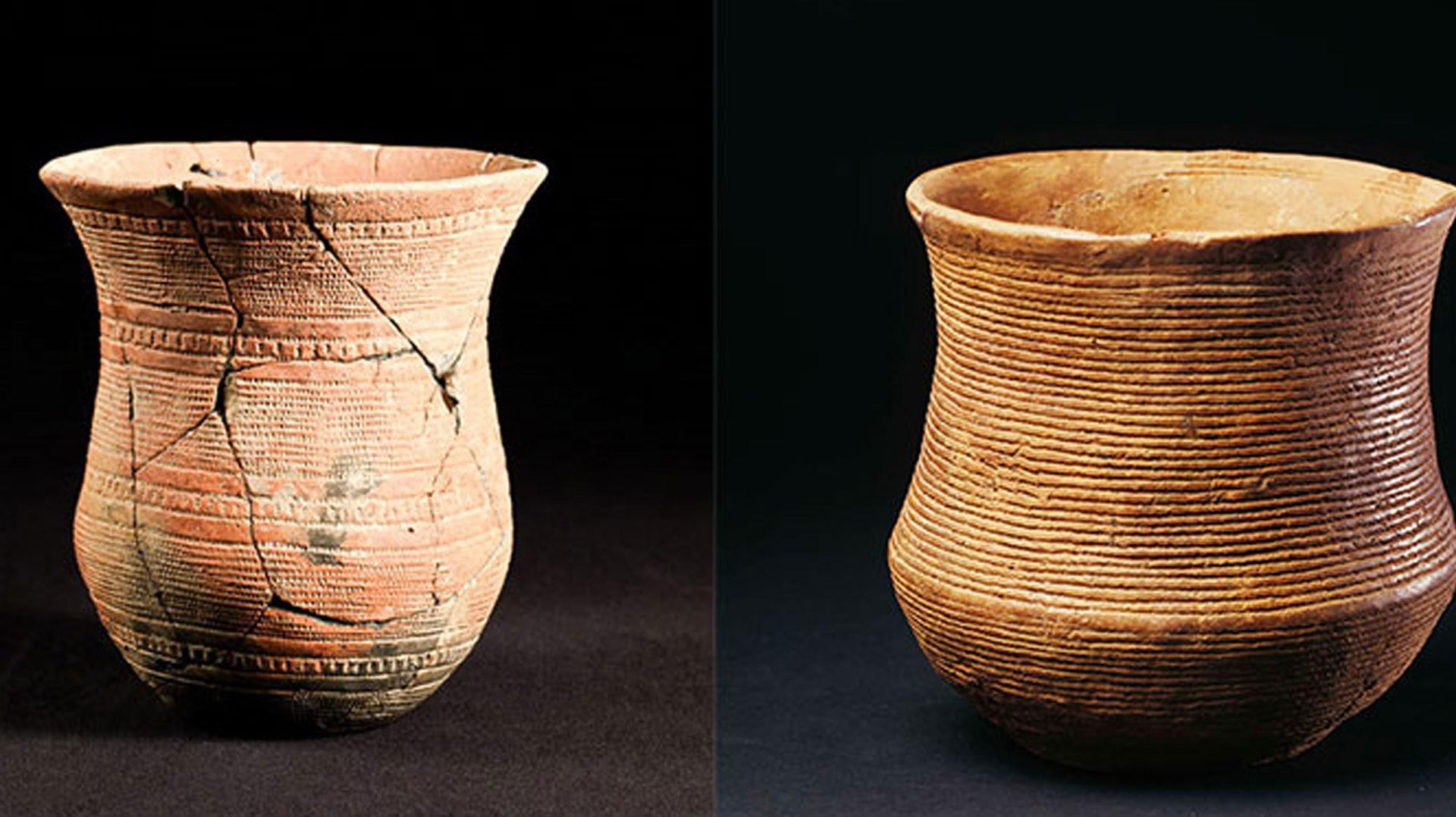

A symbolic cup made of Martian clay refers to the roots of culture, because ceramics and objects of everyday use have constituted the fundamental source of knowledge in the history of mankind, and are carriers of information up to this day.

With its many-faceted references to culture, the In Rust We Trust project takes us for a metaphorical journey through time. It should be treated as speculation rather than an implementation concept. In spite of its speculative nature, the results of the material and technological experiments can be a reference point for science and its transdisciplinary nature does not pigeonhole it in any single category. The result, i.e. the material representation of the idea, is the first attempt to create Martian utility ceramics. It is a stop on the way between what we know and what we aspire to. The project not only contributes to the discussion about the colonization of Mars, but also opens up new avenues for debate and challenge.

Artwork

In order to prepare the 3D printing experiments with the MGS-1 material, it was necessary to have a cultural and utility medium that represents contemporary culture. I designed two espresso cup models. Its shape was to symbolically refer to a catering receptacle, a cup with a certain defined function and to be a shape that would be adequate for the technology of its manufacturing, i.e. 3D printing in clay.

One of the methods of forming the first ceramic vessels before the invention of the garner wheel was to roll a long clay roll into a spiral so that the pot’s walls would form uniformly. The oldest products found date back to 13 thousand BCE. The story has come full circle, as the process of incremental production with the use of a 3D printer looks similar. However, it provides very different possibilities and the resulting structures are much more complex (Mattison 2003).

Espresso models was a carefully thought-through shape in terms of manufacturing with consideration given to cultural connotations. The G-code, i.e. the path of the printer’s head, was designed and generated with parametric tools.

Espresso is a comparatively recent method of coffee brewing. It represents the fact of and need for acting quickly, change and the rush of today’s world. Another insight is how the ISS astronauts confessed to missing the seemingly mundane things back on Earth. One of them was the smell and taste of real coffee (Donahue 2016).

Summary

Can we afford not to think about culture and message at the same time? If we are already thinking about colonizing other planets or building habitats, then, looking at this in another context, we are becoming not unlike cavemen who will once again build their culture from scratch in an empty place.

The first firings in the MGS-1 material demonstrate a similarity to terrestrial clay in terms of shrinkage and color. Thus, apart from the aesthetic and cultural aspects, the experiment also has a material science dimension. The fired samples went to a geological and chemical laboratory. Therefore, In Rust We Trust combines issues related to digital production, digital aesthetics, innovative material experiments and intercultural communication.

References

- Mattison, Steve. 2003. The Complete Potter, Quarto Publishing: London.

- Donahue, Michelle Z. 2016. “At Last, Space Brewer Lets Astronauts Make Real Coffee In A Cup”. Popular Science, February 24, 2016. https://www.popsci.com/space-brewer-lets-astronauts-make-real-coffee-at-last/ (Accessed March 15, 2020).

- Cannon, Kevin M., Daniel T.Britt, Trent M.Smith and Ralph F.Fritsche, 2019. “Mars global simulant MGS-1: A Rocknest-based open standard for basaltic Martian regolith simulants”. Icarus, Vol. 317, no. 1 (January): 470-478. https://doi.org/10.1016/j.icarus.2018.08.019

- Moscher, Dave. 2018. “Elon Musk usually reveals new details about SpaceX’s plan to colonize Mars at this annual conference. The next one is in 2 weeks, but Musk hasn’t said whether he’s going”. Business Insider. September 20, 2018. https://www.businessinsider.com/elon-musk-spacex-mars-presentation-iac-2018-9?IR=T (Accessed March 15,2020).

- European Space Agency. 2007. “True-colour image of Mars seen by OSIRIS”. European Space Agency: Space Science in Images. February, 25, 2007. http://www.esa.int/ESA_Multimedia/Images/2007/02/True-colour_image_of_Mars_seen_by_OSIRIS (Accessed March 15, 2020).

Join the conversation

xCoAx 2020: Marta Flisykowska “In Rust We Trust Project”. Can printing the first cup made of Martian clay be a symbol of a new, interplanetary, chapter of our common human history? https://t.co/zHiYWk5IUH #xCoAx2020 pic.twitter.com/QAPGSKV5vI

— xcoax.org (@xcoaxorg) July 8, 2020